This could be the most difficult and critical part of the conversion, joining the motor and transaxle with a balanced, vibration-free coupler.

November 28. I went back to Fazzio's to get more aluminum for the clutch mounting disk. I also wanted to look for something to use for the hub. I found the aluminum, then went digging around for a hub. In a back room, I found bins of hubs! Got this one for $3.25:

It fits perfectly on the motor shaft, but I will also need a compressing ring. Back to Fazzio's.

November 29. I found a pulley that is designed to slip over this hub. It can then be tightened against the hub using three bolts. More on this later.

I cut the aluminum sheet in half using the monster:

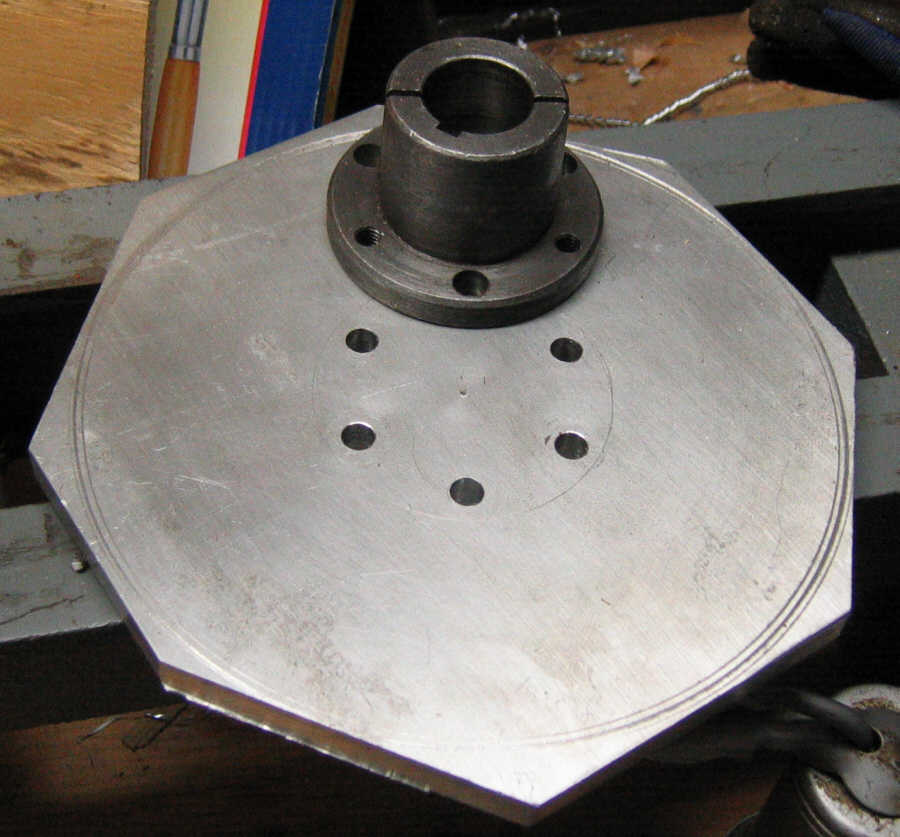

After finding the center of an 8" square piece of aluminum, I inscribed an 8" circle, a 3" circle, and punch marks for holes. I drilled out two holes so I will be able to mount the hub onto the disk. First I had to cut the corners off the plate so it could be turned on the lathe:

This saw has teeth.

This view shows the marks I inscribed on the plate:

This view shows the hub in place:

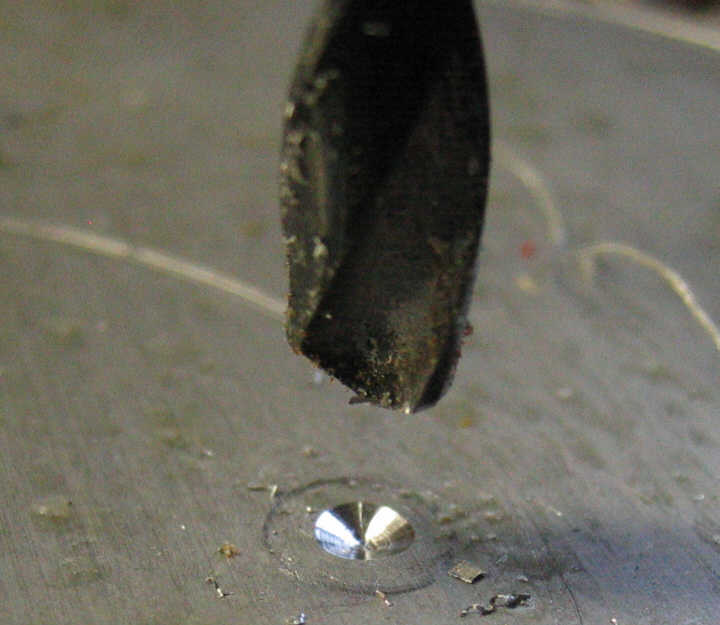

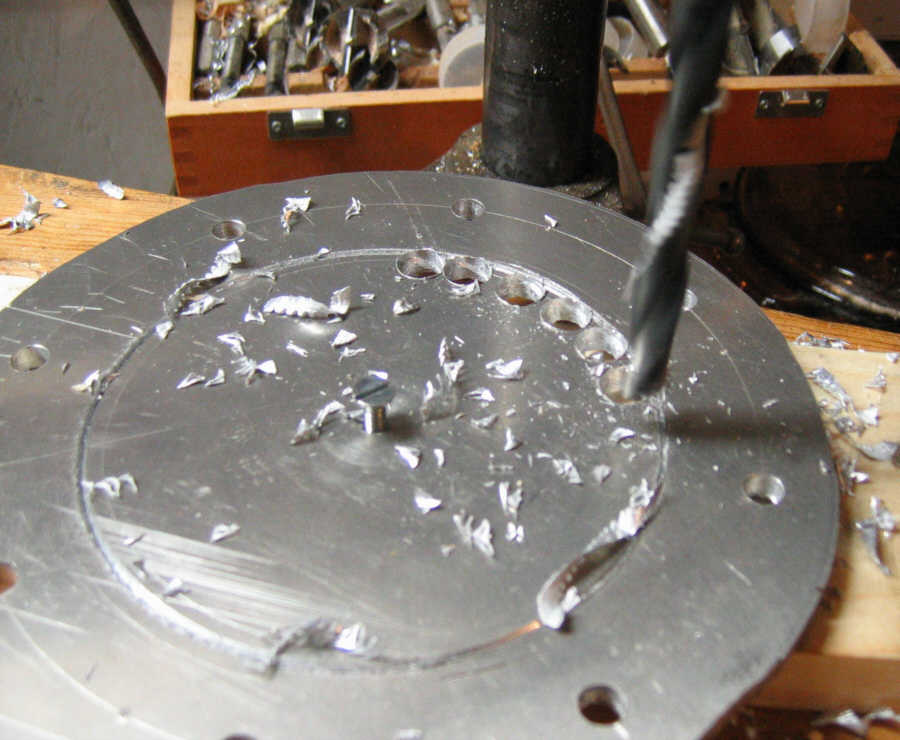

November 30. I drilled more mounting holes in the aluminum plate so I will be able to mount the disk and hub firmly in the lathe. I start the hole at the punch mark and make sure it is centered before I continue to drill:

Drill. Note the oil to keep things going smoothly and to keep things cool:

Drilled:

December 7. I made bushings to center the 5/16th bolts in the 3/8th holes in the hub. First I drilled a hole in 3/8th stock:

Then I cut off the bushing with a hacksaw:

I cleaned up the bushing on the grinding wheel and tapped it into the hub:

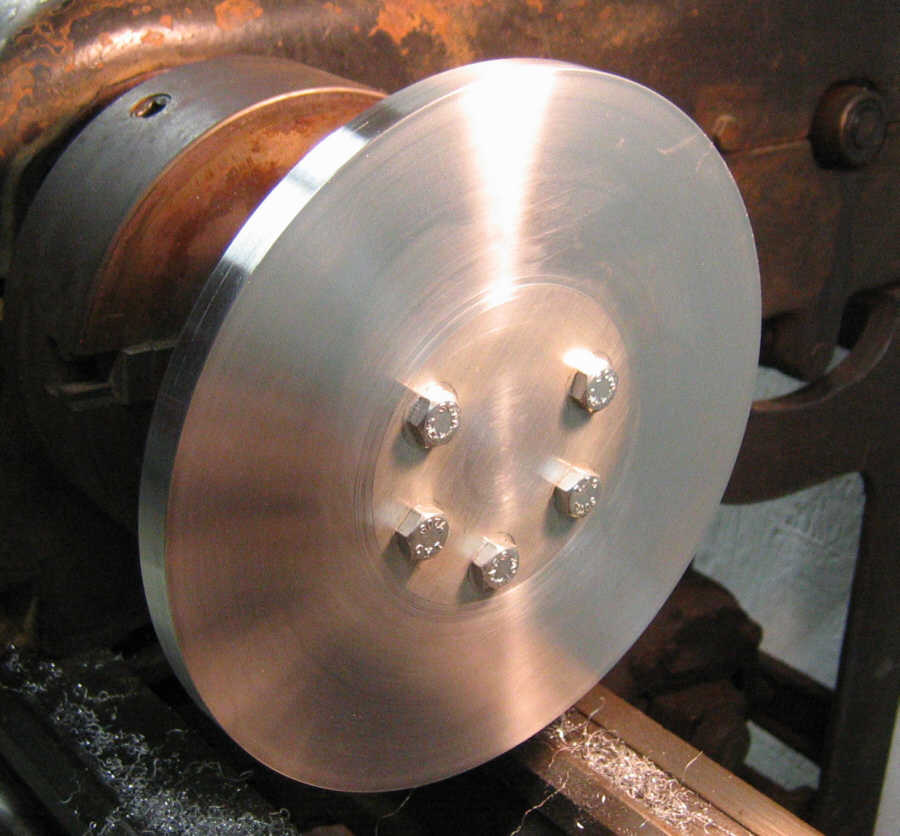

Facing the disk:

I put a metal cutting blade in the big band saw, cuts 1/2" aluminum at 3000 sfpm without heating up:

The edge needs smoothing:

You can see the mounting pulley well in this picture. It's a big pulley and may interfere with the adapter plate and motor mounting holes:

Faced, cut, then polished with a bit of steel wool:

Find the center with a dead center in the tailstock:

December 10. I drilled a center hole in the 1/2" plate just a bit larger than the transaxle shaft:

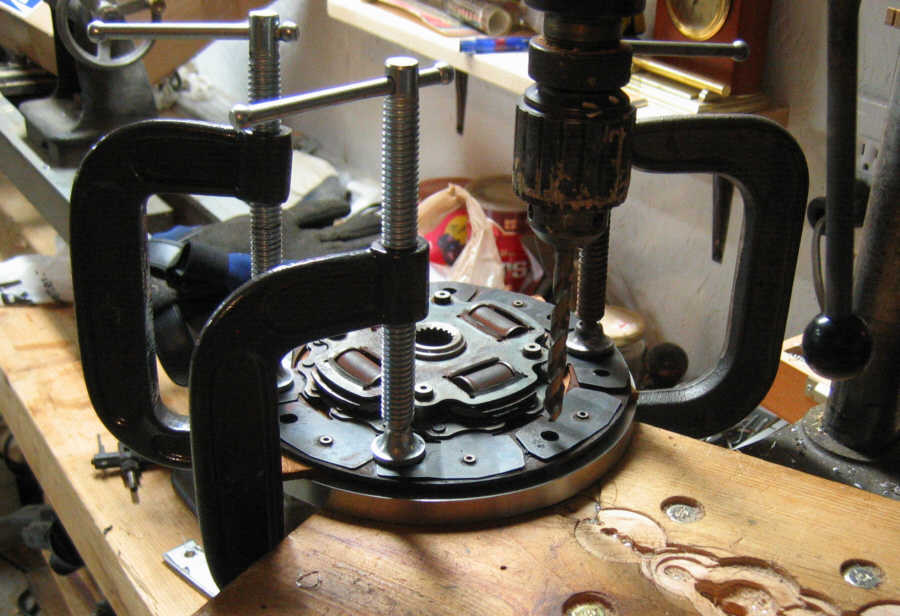

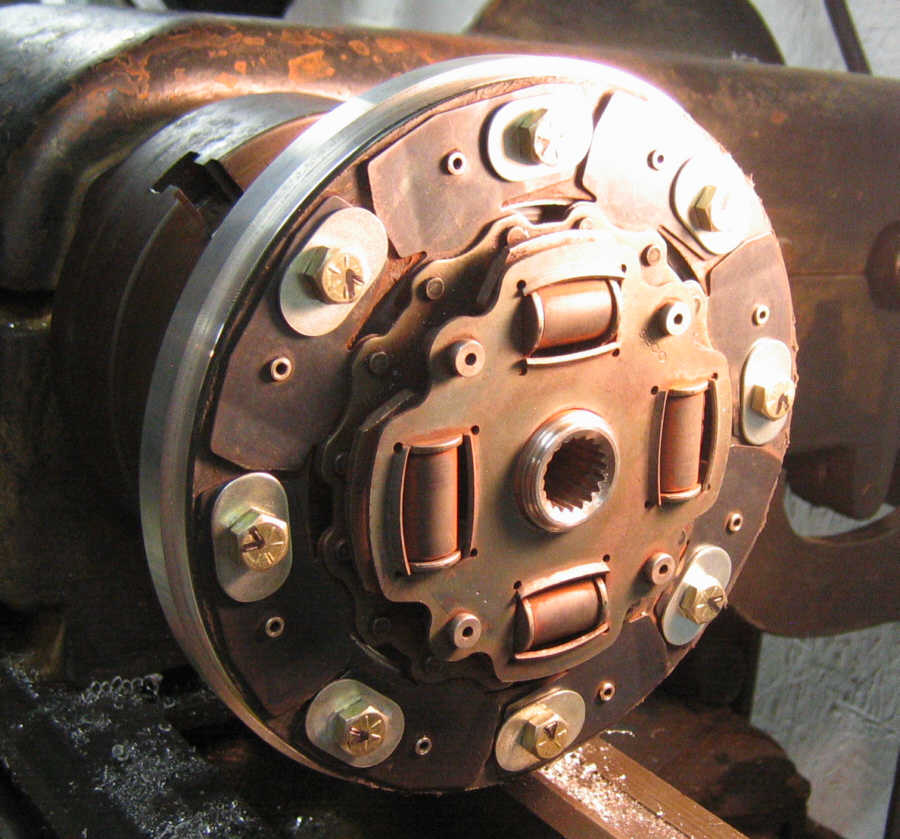

I made a jig to hold the clutch in a fixed position so that each hole would be the same distance from the edge/center. That's a cobalt drill bit to go through the clutch springs:

Clockwise from the top: (1) a 1/4" thick aluminum disk with equally spaced 5/16ths holes drilled for clutch mounting, (2) drilled clutch with grade 8 bolts, (3) clutch disk pad which fell off after I drilled through the clutch rivets and springs.

The ideal centering tool is the transaxle shaft:

With clutch:

With spacers:

Disk in place over the clutch plate.

I held the clutch plate tightly against the aluminum disk as I lifted it off the centering shaft, then clamped the clutch in place. Here it is, ready to drill using the drilled clutch spring holes as template:

December 12. I worked on the 1/4" aluminum disk this evening. I need to cut out the center to make a ring. First I tried to use a circle cutter:

1/4" aluminum is too much for this cutter, so I put a screw at the center of a board and drilled holes at the inside edge of the ring:

Holes all drilled:

I cut the center out with a reciprocating saw. Here is the rough cut ring and center:

December 13. I mounted the ring onto the aluminum disk so I could clean it up on the lathe:

It was tough getting the inside ring smooth but here it is, turned:

Clutch mounted on the disk(!):

It spins smoothly at the top speed of the lathe:

December 20. I had some balancing issues that I traced to a slightly bumped dummy shaft. I cleaned it up on the lathe and retouched the aluminum disk. I got shorter grade 8 bolts, weighed them to determine difference in mass:

I found eight bolts that didn't vary by more than 1/100th of a gram. I also weighed and sorted nuts and washers. Here is the rebalanced coupler with sorted hardware:

See the check mark on the bolts. I am happy with the way this turns on the lathe.

I put it on the transaxle shaft. You can see how the pulley compresses the hub onto the dummy shaft. Fortunately, I found this smaller pulley in the same place I found the first one, in Fazzio's "army room."

Spinning, balanced:

With the coupler nearly complete, I will continue with the adapter plate and spacers.